Energy-Saving Single-Phase Oil-Immersed Pole-Mounted Transformer

15KVA 13.8KV/0.4KV

See DetailsWhen selecting a power distribution solution, the choice between a Pad Mounted Transformer and a pole mounted unit can significantly impact performance, safety, and long-term maintenance. Both serve essential roles in electrical infrastructure, but their suitability depends heavily on the environment, load requirements, and accessibility needs. Understanding these differences helps engineers, utility planners, and procurement managers make informed decisions tailored to their specific projects.

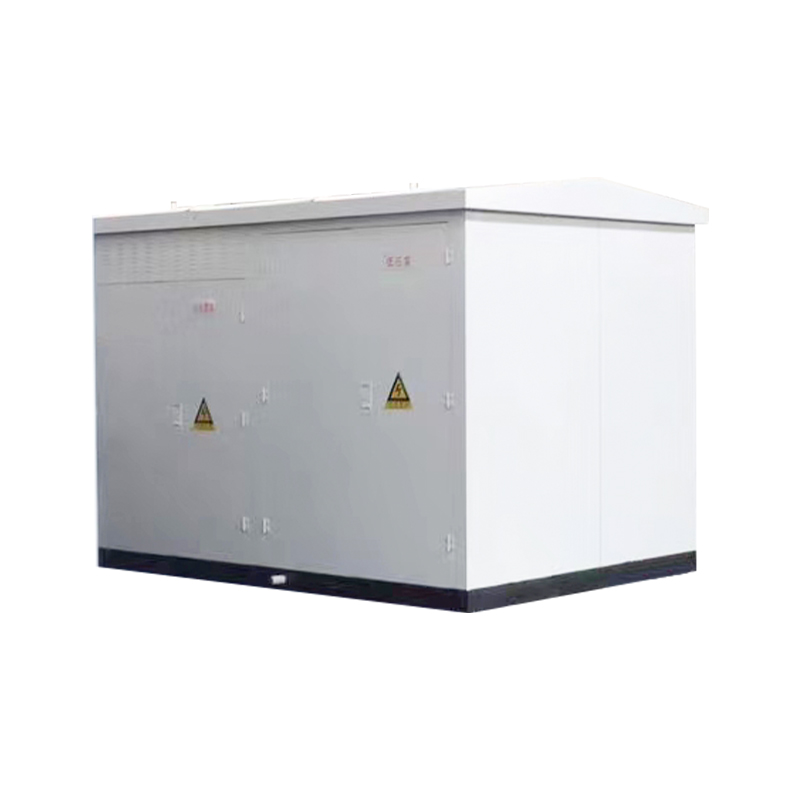

A Pad Mounted Transformer is typically installed at ground level on a concrete pad and enclosed in a locked, weather-resistant cabinet. This design makes it ideal for urban areas, commercial complexes, and industrial parks where space is limited and aesthetics matter. In contrast, pole mounted transformers are elevated and commonly used in rural or suburban settings with lower population density and more open space. The location and visibility of each type influence not only installation logistics but also public safety and system resilience.

One major consideration is safety. Pad Mounted Transformers offer a clear advantage in high-traffic environments due to their secure enclosures and reduced risk of accidental contact. They are also better suited for locations with higher vandalism risk or strict zoning regulations. On the other hand, pole mounted units require overhead lines and are more vulnerable to environmental hazards like falling branches or vehicle collisions, which can lead to unplanned outages.

From a cost perspective, pole mounted transformers generally have lower initial setup costs since they don’t require concrete pads or fencing. However, this saving may be offset over time by increased maintenance demands and vulnerability to weather-related damage. Pad Mounted Transformers , while more expensive upfront, often deliver better durability and easier access for servicing—especially in complex or large-scale installations such as airports, subways, or manufacturing facilities.

Maintenance is another critical factor. With a Pad Mounted Transformer , technicians can easily inspect and service internal components without working at height, improving both efficiency and worker safety. Pole mounted versions demand specialized equipment and training for regular upkeep, increasing labor intensity and downtime during repairs. For businesses aiming to minimize service interruptions and operational risks, this distinction becomes especially relevant.

In terms of scalability, Pad Mounted Transformers support modular expansion, allowing utilities to adapt to growing energy demands without significant redesign. Their compact footprint enables deployment in clusters or phased rollouts, making them a preferred option for developing urban grids or industrial zones. Pole mounted units, while flexible in layout, are less conducive to dense configurations and tend to reach capacity limits more quickly.

Ultimately, choosing between a Pad Mounted Transformer and a pole mounted alternative comes down to matching technical specifications with real-world conditions. At our factory, we specialize in crafting reliable, custom-configured Pad Mounted Transformers designed for diverse applications—from residential communities to heavy industrial sites. Our engineering team works closely with clients to ensure every unit meets the highest standards of performance, safety, and longevity, helping you build smarter and more resilient power systems.

Contact Us