Three-Phase Transformer With Oil Pillow

630KVA 11KV

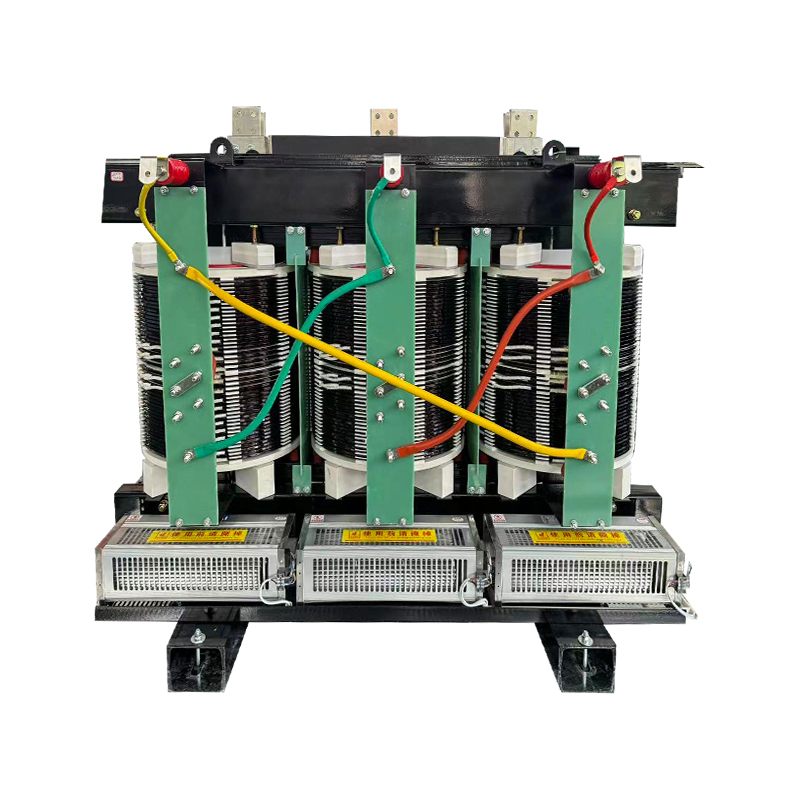

See DetailsDry-type transformers are playing an increasingly important role in shaping how cities manage their electrical distribution. As demand for safer, cleaner, and more flexible infrastructure grows, cast resin dry-type units are stepping into load centers that once relied on bulkier, oil-immersed solutions. These transformers are not just fire-retardant and self-extinguishing by design—they also allow for tight integration into compact environments like underground substations, high-rise basements, and rooftop electrical rooms where safety and space optimization are critical.

In densely populated areas, decentralized power systems are gaining traction because they reduce transmission losses and improve grid responsiveness. Dry-type transformers help bring these systems closer to end users without introducing the risks associated with flammable insulation oils. Their epoxy resin insulation keeps the windings sealed against moisture and contaminants, making them an ideal choice for areas with high humidity, pollution, or dust exposure. This robustness means they can be installed near their load points with minimal environmental preparation, cutting down on auxiliary infrastructure and associated costs.

At the technical level, dry-type units are designed to withstand significant thermal and mechanical stress without degradation. Because the insulation is solidified in resin, there's no risk of oil leaks or fire propagation, which makes them compliant with strict safety regulations in airports, hospitals, and shopping complexes. As decentralized grids move toward integrating more solar, battery, and microgrid systems, dry transformers bring another advantage: their stability under load fluctuations. These transformers maintain voltage regulation and thermal performance even during irregular load cycles, which is typical in distributed energy applications.

Transport and installation of these transformers is also easier in confined urban settings. There’s no need for oil containment systems or fire suppression zones, and their enclosure designs can be tailored to meet project-specific space and cooling constraints. Their relatively low noise output is another reason they’re used in commercial and residential zones. From a logistical perspective, modular dry-type transformer assemblies can be pre-tested, factory sealed, and shipped ready to drop into a prefabricated substation or a retrofitted service room.

Dry-type transformer systems also meet global efficiency and safety standards, which is essential for developers involved in multi-site smart grid projects. Their compatibility with international voltage classes and frequency ranges, along with low partial discharge levels, makes them reliable choices for clients seeking long-term performance with minimal intervention. Routine maintenance is typically limited to visual inspections and airflow checks, since there are no moving parts or fluid systems that require regular servicing.

As manufacturers, we understand that the needs of decentralized power setups vary from project to project. That’s why we offer design flexibility, quick production lead times, and engineering support to help match the transformer configuration to the site’s electrical, spatial, and environmental requirements. Whether you're specifying equipment for a new data hub or upgrading a utility network in a historical district, a properly selected dry transformer can add both reliability and value to your power strategy.

For projects that demand a safe, low-maintenance, and high-performance solution, dry-type transformers continue to prove themselves not only as a practical choice, but also as an investment in grid resilience and long-term efficiency. As urban power networks become more localized and demand-side controls more advanced, these transformers are set to remain at the heart of smart, compact energy distribution systems.

Contact Us